Ceramic PCB board is a kind of special board with good thermal conductivity, insulation and high dielectric constant, so it is widely used in end products in the field of heat dissipation. Compared with ordinary PCB boards, ceramic PCB boards have the following differences:

1、The material is different: ceramic PCB board using inorganic materials, the core material is usually aluminium trioxide or aluminium nitride; and ordinary PCB board using organic materials, commonly used FR4 glass fiber board. Ceramic PCB board is fragile, can not be multi-layer pressing, while the ordinary PCB board can be multi-layer pressing.

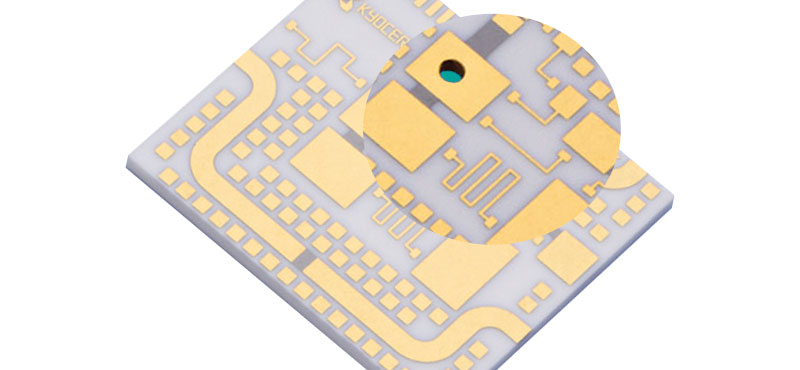

2、Different performance and application: ceramic PCB boards are mainly used in industries with greater heat dissipation needs, such as high-power LED lighting, high-power modules, high-frequency communications, rail power supply and other fields. While the ordinary PCB board is more widely used, mostly used for civilian commercial products.

Ceramic PCB board and high-frequency board difference:

1、Different materials: ceramic PCB board is mainly used in aluminium oxide or aluminium nitride; and high-frequency boards are usually made of Rogers (Rogers), Yalong (Arlon), PTFE and other materials, with a low dielectric constant and high-frequency communication speed.

2、Different applications: ceramic PCB boards are widely used in refrigeration chips, high-power modules, automotive electronics and other fields, especially for applications that require heat dissipation. And high-frequency boards are mainly used in high-frequency communications, aerospace, high-end consumer electronics and other fields.

3、Combined with the application: in some high-frequency communication fields, due to the greater need for heat dissipation, often need to combine the use of ceramic PCB boards and high-frequency boards, such as the production of high-frequency ceramic PCB boards.

So, how to identify the quality of ceramic substrate advantages and disadvantages ?

1、Look at the ceramic substrate quality parameters: quality assurance of the ceramic substrate should be the choice of chemical stability (high temperature resistance, resistance to strong acids and alkalis), thermal conductivity and so on with many good quality substrate materials for the production of this parameter information can be consulted or view the specific product manufacturing instructions for understanding

2、Look at the ceramic substrate fine workmanship: high-quality ceramic substrate requirements between the distance between the electronic components, bonding tightness and other strict requirements, of course, the appearance of the plate high flatness, edge flatness, etc., can also reflect the quality of its processing

3、Through the trial: ceramic substrate is a major advantage of its thermal conductivity, you can let the plate work for a period of time, and then cut off the power to stop its work, test its temperature and the entire circuit current flow rate, such as the temperature is too high means that its thermal conductivity is not good not good quality ceramic substrates

4、Through the understanding of ceramic substrate manufacturers information: ceramic substrate manufacturing manufacturers formal, with a variety of qualifications, often means that its production and manufacturing is through the formal, strict production processes and requirements, the selection of materials will also be guaranteed, of course, but also to understand the ceramic substrate the corresponding brand reputation and user evaluation, which to a certain extent can also be a direct manifestation of ceramic substrate quality of the situation!