Increasing criminal activities across the world coupled with stringent government controls have led to a growing demand for security systems. Increasing competition in the security market due to the introduction of advanced technologies is driving the demand for security automation. The growing demand for security systems such as access control systems and video surveillance systems for real-time monitoring has led to an increase in the number of security infrastructures around the world.TORTAI, as a specialised provider of security electronics assembly and manufacturing services, has a deep understanding of the unique challenges faced by companies in the security industry when developing and manufacturing electronic products for security systems. In order to help our customers bring their products to market quickly and efficiently, we provide full service support, including prototyping, production assembly manufacturing, and quality control. Through our expertise and experience, we are able to optimise designs, shorten development cycles and increase production efficiency, thereby reducing costs and enhancing market competitiveness.

In order to meet our customers’ security PCB assembly manufacturing requirements, TORTAI must ensure that their products are of high quality, reliability and safety. In order to achieve our goals, we need to adopt a series of quality control measures, such as ISO 9001:2015, ISO 14001:2015 quality system standards and security industry implementation standards, to ensure that our products meet the standards of safety, reliability and performance requirements.

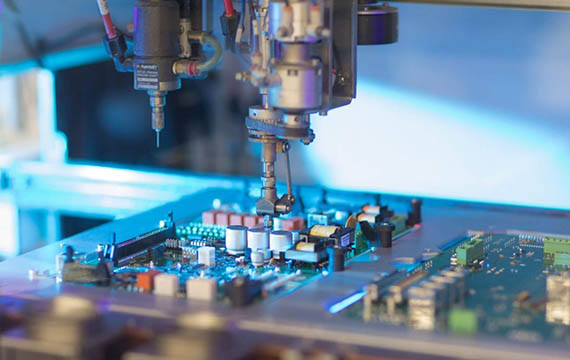

TORTAI as a full service provider of security electronics assembly manufacturing. The team has a wealth of industry experience and is committed to helping our customers quickly turn concepts into marketable final products. We specialise in rapid prototyping, PCB design and layout, electronic PCBA assembly and testing. In addition, our team of professional engineers has deep experience in electronics manufacturing, with electronics engineers, BOM engineers, structural design engineers, and electronics procurement engineers to ensure the safety and reliability of all processes.

TORTAI provides DFM report before sampling, which can help customers avoid obvious mistakes and reduce NPI time.

We can also help customers design functional test equipment to ensure product quality.

TORTAI can provide test reports on soldering reliability, soldering process and product reliability.

Security Electronics Assembly And Manufacturing Services

|

|

Design & Engineering• Printed Circuit Board Design • BOM Review • Rapid Prototyping |

Electronics Manufacturing• Printed Circuit Board Manufacturing • Printed Circuit Board Assembly • Integrated Manufacturing • Electromechanical assembly |

|

|

Testing and Inspection• Feed Quality Control • AOI Optical Inspection • FAI First Article Inspection • X-ray Inspection • ICT Testing • DIP Insert AOI Test • Aging Test • Functional Test • Electrical Performance Test • FCT Function Test |

Value Added Services• Component Sourcing • Logistics |

Complete Quality Certification System

ISO9001:2015, ISO13485:2016,ISO14001:2015, UL, SGS, RoHS.

Quality and service are the fundamental reasons why medium and large customers have been choosing us for a long time.

Company Overview

| Company Name | Tortai Technologies Co., Ltd. |

| Founded | 2007 |

| Company Size | 4,600 Square Metres of Production Halls |

| Quality Certification | ISO9001 Quality Management System • ISO13485 Medical Device Quality Management System

ISO14001 Environmental Management System |

| Product Certification Scope | UL • RoHS • SGS • REACH |

| Business Scope | PCB Fabrication • Component Purchasing & Inventory Management • SMT SMD Processing • DIP Insertion Soldering • PCBA OEM • Conformal Coating • Electronic Potting • PCBA Testing • Box Build Assembly |

| value-Added Service | NPI New Product Introduction • DFX Analysis • Rapid Prototyping • Programming • SMT Stencils • Fixtures • Repair Service |

| Service Areas | Transportation • Energy • Medical • Security • Communications • AI&IoT |

| Technical Team | Electronics Engineer • BOM Engineer • Structural Engineer • Electronics Procurement Engineer |

| Production Equipment | High Speed YAMAHA SMT Machine • Nitrogen + Vacuum Reflow Oven • 10 Temperature Zones Reflow Oven • Wave Soldering • Three-proof paint automatic spraying line •Precision Potting Machine |

| Testing Equipment | Automatic Material Checker • Solder Paste Inspection (SPI) • Auto Optical Inspection (AOI)for SMT • First Article Inspection (FAI) • X-Ray Testing • In-Circuit Test (ICT) • Function Testing(FCT) • Electric Performance Testing • AOI for DIP • Aging Test |

| SMT lines | 6 assembly lines Automatic Board Loading Machine-DM900, Automatic Printing Machine-GKG Gse, 3DSPI (3D Solder Paste Inspector)-S8030, Yamaha Mounter-YSM10, Yamaha Mounter-YSM20, Nitrogen Vacuum Reflow Soldering Ovens-HX-F1030H, AOI Automatic Optical Inspection-ALD525L. |

| DIP production lines | 2 assembly lines Wave Crest Furnace -350 |

| Three-Proof Paint Spraying Line | 1 assembly line Automatic Coating Machine – iCoat-3, Infrared Curing Furnace (2 m)-iCure-2 |

| Box Build Assembly Line | 2 assembly lines |

| Automatic Precision Potting Machine | 4 table Automatic Glue Filling Machine-XH-001 |

Why Choose TORTAI

|

|

One-Stop PCB Assembly ServiceWe provide customers with a complete supply chain, PCB Manufacturing + Electronic Components Procurement + SMT Mounter + DIP Insertion Soldering + PCBA Testing + Three-Proof Paint Spraying + Electronic Potting Adhesive + Low Voltage Overmoulding Injection + Finished Product Assembly |

Rich Industry ExperienceWe have a wealth of experience in the security industry, providing customers with DFM, DFA, DFT and other design optimisation and electronic component selection analysis. Ensure that your products are manufactured accurately and efficiently. |

|

|

ServiceBy business, engineering, quality of the project-type organisational structure, project-specific responsibility system as the guide, the project manager for the service specification supervisor, for pre-sales and after-sales service to provide rapid response, feedback. |

Signed Confidentiality AgreementsTORTAI maintains the highest standards of confidentiality by signing confidentiality agreements with our clients, and all document output must be approved to ensure 100% document non-disclosure. |

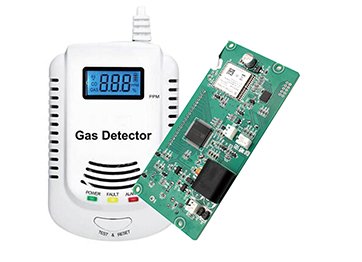

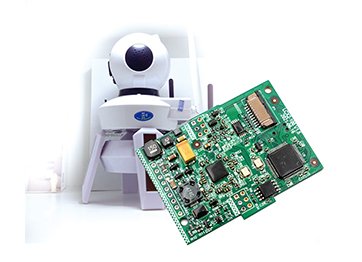

Security PCB Assembly Application Scope

1、Home Security System 2、Commercial Security System

3、Factory Security System 4、Campus Security System

5、Hospital Facility Security System 6、Hotel Security System

7、Public Facility Security System 8、Security System for Financial Institutions

9、Transport Facility Security System 10、Building Access Control System

11、Video Surveillance System 12、Fire Alarm System

13、Door and Window Alarm System 14、Electronic Fence System

15、Security Lighting System 16、One-key help system

17、Surveillance System 18、Facial Recognition System

19、Fingerprint Identification System 20、Security Access Control System

21、Security Alarm Button

Security PCB Assembly Manufacturing Service Case