TORTAI has passed ISO9001 quality management system, ISO13485 medical device quality management system certification, ISO14001 environmental management system, has a strong engineering quality management team and a professional electronic components procurement team, the products comply with IPC-A-600 & IPC-A-610 standards. Our products comply with IPC-A-600 & IPC-A-610 standards, so that the quality and production technology of all our products are in line with international standards and customers’ requirements. We provide value-added services to satisfy our customers, such as manufacturability check (DFM/DFA), and help our customers successfully complete the rapid transition from design to mass production as a one-stop PCB service provider.

PCBA Production Process Flow

01–Material Procurement

02–Receiving/Storage

03–Feed Inspection

04–Warehousing And Issuance of Materials

05–Material Baking

06–Brush Solder Paste

07–Solder Paste Inspection (SPI)

08–High Speed YAMAHA SMT Machine

09–First Article Inspection (FAI)

10–Reflow Solder

for-SMT-1.jpg)

11–Auto Optical Inspection (AOI)

12–X-Ray Testing

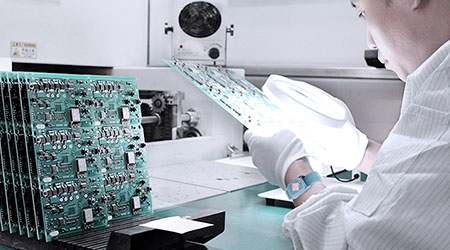

13–FQC Inspection

14–IPQC Patrol Inspection

15–OQC Inspection

16–Pre-Processing

17–Manual Plug-In

18– AOI for DIP

19– DIP Wave Soldering

20–Post-Furnace Pick-up Jig

21– In-Circuit Test (ICT)

22– Depaneling

23– Panel Cleaning

24–Programming

25–Function Testing

26–First Article Inspection (FAI)

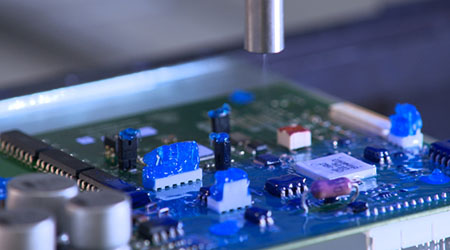

27–Conformal Coating

28–Box Build Assembly

29–Finished Product Function Test

30–OQC Inspection Before Storage

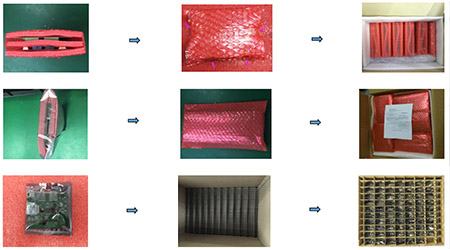

31–Packaging

32–Put Into Storage

33–Deliver From Godown

SMT Workshop Error Proofing System

1.MES Management System:

(1) Automated production plan development and issuance.

(2) Monitoring of the product production process, including production process parameters, equipment status, personnel operations, etc.;

(3) product quality management;

(4) material management;

(5) Inventory management

(6) Finished goods warehousing management.

2.Solder Paste Inspection (SPI)

3D Solder Paste Inspection (SPI) is a technology used for soldering process control in the electronics manufacturing industry. By using optical or laser scanning technology, it can quickly and accurately detect the quality and accuracy of solder paste during the soldering process.

3.Auto Optical Inspection (AOI)for SMT

(AOI ) Automatic Optical Inspection is an advanced technological device mainly used for quality inspection of circuit boards and assemblies in the electronics manufacturing industry. It can quickly and accurately detect defects, errors and anomalies on circuit boards by using optical technology and image processing algorithms.

4.First Article Inspection (FAI)

FAI First Article Inspection is the process of first article inspection of PCBA (Printed Circuit Board Assembly). In the PCBA manufacturing process, first article inspection is a key quality control step to verify that the first article of a new product or process meets the design requirements and specifications.

5.In-Circuit Test (ICT)

In-Circuit Test (ICT) test is a commonly used electrical test method to verify the correctness of the circuit connections on the PCBA and whether the electrical performance meets the requirements.ICT test is usually carried out in the final stage of PCBA manufacturing to ensure the quality and reliability of the PCBA.

6.X-Ray Testing

X-Ray Testing is a non-destructive test method used to check the quality of soldering and assembly inside a PCBA. By using X-ray technology, details such as solder joints, pads, component locations and connectivity inside the PCBA can be viewed to detect possible defects and problems.

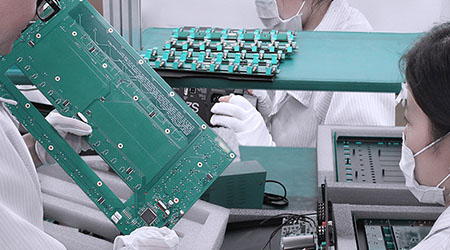

7.PCBA Function Testing

PCBA (Printed Circuit Board Assembly) functional test is a series of tests on the assembled circuit board, designed to verify that the various components and functions on the circuit board work properly.

8.AOI for DIP

DIP Insert AOI Inspection is a method of inspecting the quality of DIP Inserts using an Automated Optical Inspection (AOI) system.DIP Inserts are a commonly used form of electronic component packaging, and DIP Insert AOI Inspection can be used to achieve the correctness and quality of the DIP Inserts on a Printed Circuit Board (PCB).

9.PCBA Programme Burning

PCBA programme burning is the process of loading pre-written programme code into a microcontroller or memory on a PCBA (Printed Circuit Board Assembly).

10.PCBA Electric Performance Testing

PCBA Electrical Performance Testing is the process of evaluating and verifying the overall electrical performance of a circuit board after assembly. It aims to ensure that the PCBA can work properly in actual use and meet the design and specification requirements.

11.PCBA Aging Test

PCBA Aging Test is the process of evaluating and verifying the reliability of PCBAs under prolonged use and environmental changes. It aims to simulate the aging of PCBA in actual use to determine whether it can maintain stable and reliable performance in long-term operation.