PCBA (Printed Circuit Board Assembly) functional test is a series of tests on the assembled circuit board, designed to verify that the various components and functions on the circuit board work properly.

1、Electrical testing: By testing the electrical connections, voltages, currents and other parameters on the board to ensure that the electrical performance of the board meets the design requirements. This can be done through the use of test fixtures and test instruments (e.g. multimeters, oscilloscopes, etc.).

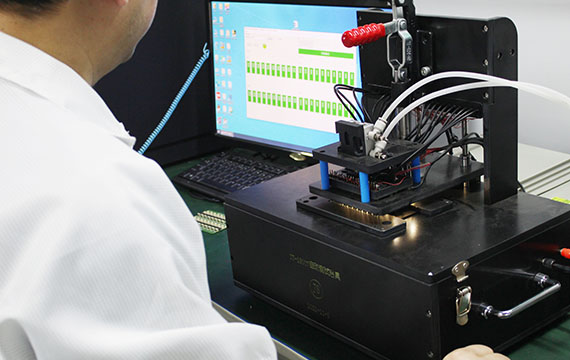

2、 Functional testing: Testing the operation of individual components and functions on a circuit board by simulating or using actual input signals. For example, for a control circuit board, various commands and signals can be input to test the response and output of the control circuit as expected.

3、Communication Test: For circuit boards with communication functions, it is necessary to test whether the communication between them and other equipment or systems is normal. This can include testing the data transmission of serial communication interfaces (e.g., UART, SPI, I2C, etc.), as well as network communication interfaces (e.g., Ethernet, wireless communication, etc.) connection and data transmission.

4、Temperature testing: Some boards may need to work in high or low temperature environments, so temperature testing is required to verify the board’s performance and reliability under different temperature conditions.

5、Reliability testing: Evaluate the reliability and durability of a circuit board by simulating its operation over a long period of time or in a specific environment. This can include vibration testing, shock testing, temperature cycling testing, etc.

The purpose of PCBA functional testing is to ensure that the board works properly in actual use and meets design and specification requirements. By conducting comprehensive functional testing, product quality and reliability can be improved, failure rates can be reduced, and customer needs can be met.