PCBA circuit board three-proof paint can effectively achieve insulation, moisture-proof, anti-leakage, anti-vibration, dust-proof, salt spray and other protection effects, so as to enhance the reliability of the circuit board, increase its safety factor, and effectively delay the use of life.

PCBA circuit board paint is used in a wide range of high technology applications, home appliances, military electronics, aerospace, medical electronics and other high-end circuit boards, which can improve the quality of PCBA boards and significantly reduce the rework situation. In addition, the emergence of new industries, charging piles for electric vehicles, and the widespread use of wireless planes have further expanded the scope of use of triple anti-pattern paint. At present, it has become a major trend to coat PCBAs with three-proof paint for protection.

The three-proof paint is used to protect PCBA boards and related equipment from environmental damage. Its function is to improve the reliability of the product, especially in harsh operating environments. The coating protects the electronic product from external factors such as extreme heat, humidity, moisture and dust. It also protects electronic products from internal factors such as corrosion, whisker growth, and in-system

short circuits in the system. In short, the three-proof varnish acts as an insulating layer, ensuring that different components can function properly and preventing premature PCB failure.

Comparison of Coating Machine and Traditional Coating Process

Traditional coating

(1) Brush coating: air bubbles, waves, and brush stripping;

2)Row brush coating: too slow and accuracy can not be controlled.

(3) Soak the whole piece: too wasteful paint, slow speed.

(4) spray gun: to fixture protection, too much drifting

Coating machine coating:

(1) Accurate setting of paint volume, paint position and surface area, and no need to wipe the board after painting.

(2) If some plug-in components are widely spaced from the edge of the board, they can be painted directly without the use of a fixture, which saves the staff.

(3) No gas is emitted to ensure a clean working environment.

(4) All substrates do not need to be covered with carbon film using a fixture, eliminating the possibility of collision.

(5) Uniform coating thickness of the three-proof paint improves production efficiency and product quality, while avoiding paint waste.

Automatically coated boards

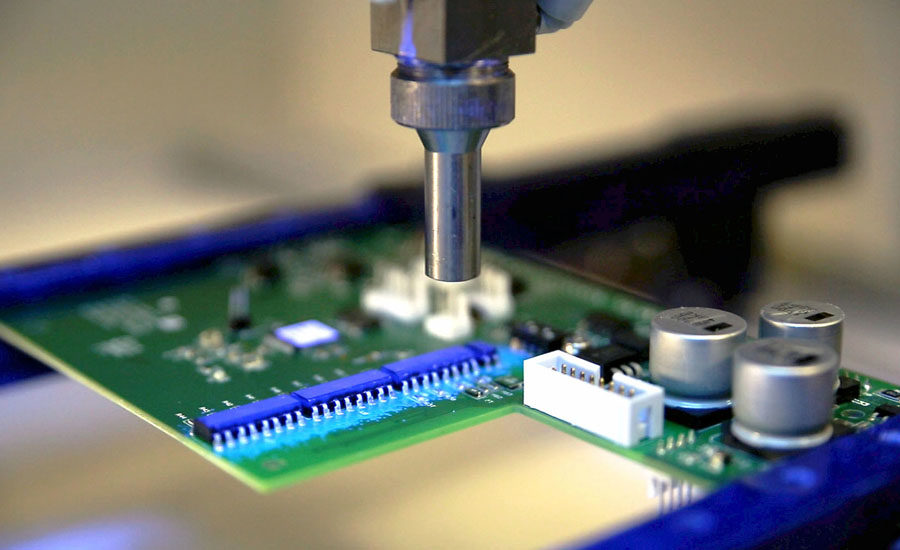

The PCBA automatic three-proof paint coating machine is an intelligent coating machine designed specifically for coating three-proof paint. The coating machine is equipped with the latest computer control program, which enables three-axis linkage, and a camera positioning tracking system to precisely control the coating area.

The three-proof paint coating machine is called three-proof paint coating machine, three-proof paint spraying machine, three-proof paint spraying machine, three-proof paint spraying machine, etc. It is specially designed to control the fluid and cover the surface of PCB with a layer of three-proof paint, such as covering the surface of PCB with a photoresist by dipping, spraying or spin coating.

OEM electronic manufacturing OEM factory specializes in PCBA coating machine mainly used for product process in which glues, paints, and other liquids are precisely sprayed, painted, and dripped onto each product at precise locations, and can be used to achieve line, circle, or arc shape.

EMS Electronics PCBA full board tribo coating machine, full board coating machine provides a clean, highly efficient and fully automatic tribo coating process. The precisely controlled spray valve ensures uniform tribo coating of 0.05mm thickness, which is a life-changing improvement over manual spraying, dipping and brushing, and greatly enhances production efficiency and product quality.

OEM Electronics Factory Specialized in selective tribo coating machine, the selective coating machine provides a clean, highly efficient fully automatic selective positioning tribo coating process that avoids spraying outside the selected area, eliminating the need for overcoating, de-coating and repair. Precisely controlled spray valves ensure uniform tribo coating at 0.02mm thickness.

There are various names for three-proof paint, such as three-proof adhesive, moisture-proof adhesive, insulating adhesive, moisture-proof paint, protective paint, protective paint, coating adhesive, coating adhesive, water-proof adhesive, moisture-proof oil, three-proof oil, three-proof agent, protective agent, moisture-proof agent, conformal coating, conformal coating, conformal coating, common coating, and the English name Conformal Coating.

Types of Three-proof Paint.

The curing method of three-proof paint is divided into room temperature curing, heat curing and light curing, etc. The chemical composition of three-proof paint can be mainly divided into acrylic resin (Acrylic, Type AR), epoxy resin (Epoxy, Type ER), silicone (Silicone, Type SR), polyurethane resin (Urethane, Type UR) and poly-toluene (Parylene, Type XY). Parylene, Type XY) five major categories.