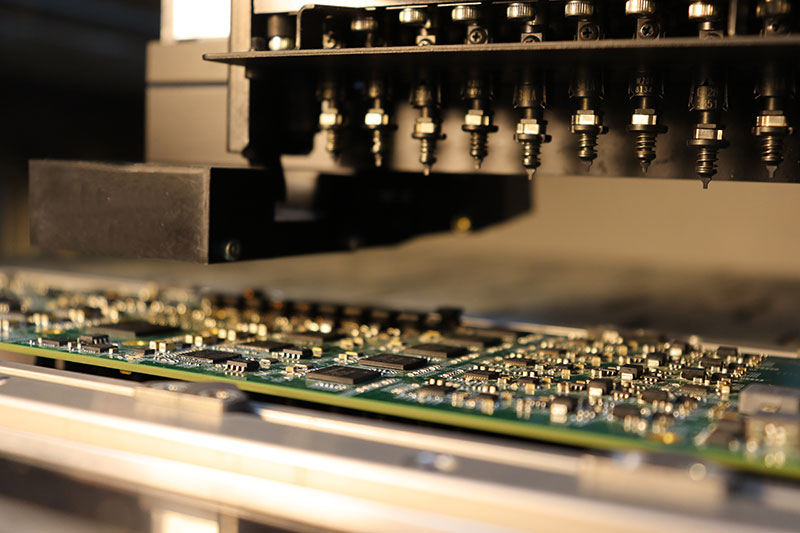

Recently found in the reception of customer inquiries, often encounter customers say we need to do PCB assembly small batch proofing, you can do it?of course! We are sure that we can do it, because Tortai Electronics is a small and medium-sized production and small and medium-sized prototyping can do the company, Tortai Electronics for small and medium-sized prototyping customised a special production line for prototyping. Equipped with Yamaha SMD machine, Sweden imported solder paste printing machine, solder paste tester, vacuum nitrogen reflow soldering, selective wave soldering, Auto Optical Inspection (AOI), X-Ray Testing, and professional SMT processing technicians.

When we communicate in depth, many customers will be in the cost of the key nodes there is a great deal of doubt, why our sampling unit price is so much higher than the price of mass production.

In fact, over the years we often encounter because of certain details of the offer, the customer does not reply to the message does not contact the situation, today according to the PCB assembly processing small batch sampling price why will be higher to do share.

A lot of customers are actually clear in their own minds, small batch sampling is to be higher than the batch price, but may be in the heart of the threshold is also higher than a 1 yuan or 3 yuan. After all, we feel that a few PCBA boards or dozens of pieces, is a preliminary sampling to verify the functionality of the product is in line with the design indicators and customer demand. After all, it is a risky project, do not want to invest too much.

High price! PCB assembly and processing plant to do what the work?

Any PCB assembly processing prep work is the same, such as material inspection, SMT chip processing machine programming, PCB positioning, solder paste printing, SPI solder paste testing, chip processing, welding, AOI testing, functional testing, first piece confirmation and so on. At first glance, they are all routine processes, so where exactly is it expensive?

The disadvantage of small batch sampling lies in the SMT SMD processing points are too small, tens of thousands of points or hundreds of thousands of points counted a lot, although the on-line sticker is very fast, but purchasing, engineering, production, quality, operators, warehouse ……. All the departments of the relevant personnel, as well as the relevant equipment all to be used up.

The most important thing is not centralised assembly, in and out of the turn line, change materials. So in accordance with the minimum consumption of PCB assembly and processing plant, you do 10 boards per PCB board assembly and processing costs combined is not a small amount of money. You think it’s expensive, because the products you do only buy a hundred dollars. If the follow-up has a large number of products to share the pre-sampling, trial production of the input is very cost-effective.

So in the case of small quantities, the so-called loss, more time loss. After all, a skilled operator a day’s salary are more expensive. In the same time under the large volume assembly production efficiency is higher, not to consume a lot of time, that is, and not wasted in the preparation work. There is a turn of the line, change the material out of the time in and out, so that can be highly efficient, but also to save a variety of time costs, labour costs, machine wear and tear and so on.

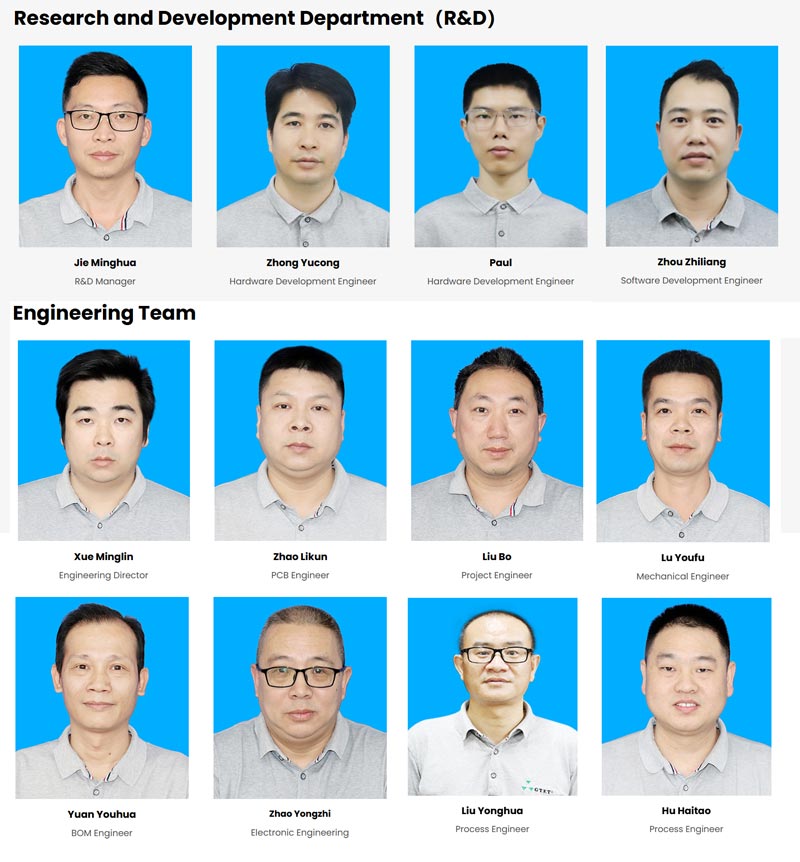

Although the PCB assembly of small quantities and sampling no special process, but as a PCB assembly company to invest in the cost is relatively high, Tortai Electronics as a one-stop electronic assembly manufacturing services company, which is equipped with a professional R & D team, engineering team, quality team, production team have 10 years + industry experience. Can be for the early PCB assembly sampling stage to assess the risk, process control, cost control and escort. R & D team from concept to product, to provide you with one-stop electronic manufacturing services. According to your needs to develop personalised customised PCBA solutions and ODM development solutions, to provide the following services:

1、Project evaluation, programme development

2、Hardware design, software design

3、Old product upgrade, old product optimisation

4、Product certification technical support

5、Project landing before the accurate avoidance of problems and risks that may affect the project.