R&D Business Overview

Tortai Electronic Technology is a professional electronic design and manufacturing service provider, dedicated to providing comprehensive and excellent services and solutions to our customers. We initially won the trust of our customers with our superb PCBA (Printed Circuit Board Assembly) foundry services, and now we are actively expanding to a full range of ODM (Original Design Manufacturing) design services, aiming to provide more cutting-edge and comprehensive support to our customers.

As your preferred partner, we not only provide high-quality, highly reliable PCBA manufacturing services, but are also committed to transforming your innovative ideas into market-competitive electronic products. Our design team has a wealth of industry experience and technical expertise, especially in the field of communications with a deep accumulation of technology and project practice experience.

Our newly added ODM development department will further enhance our value in the industry chain, providing customers with one-stop solutions from concept generation, blueprint design to finished product manufacturing.

Our ODM Service Advantages

|

|

|

Efficient Design Process and Quality Management: We utilize advanced design tools and processes to enhance efficiency and quality. Our comprehensive quality management system monitors the entire design process, setting clear goals with clients to ensure high-quality, on-time project delivery. |

Extensive Technical Experience: We’ve assembled a dynamic development team with ample experience and a strong sense of responsibility. We look forward to leveraging our expertise to deliver efficient and innovative solutions for our clients. |

|

|

|

Comprehensive Electronic Design Services: We provide end-to-end electronic design services, from concept to mass production, covering various fields such as communications, medical, and industrial control. With our extensive innovation experience, we help customers achieve product differentiation and create unique competitive advantages. |

Customer-Centric Service Model: We deeply understand our customers’ needs, offering tailor-made design solutions and working closely with them to respond promptly to feedback and changes. By focusing on cost-effectiveness, we help customers optimize their products and enhance their competitiveness. |

Our ODM Service Process

Requirements Communication And Project Evaluation

- Communicate With Clients to Understand Their Business Needs, Technical Requirements, Time schedule And Budget.

- Evaluate The Feasibility And Risk of The Project, And Provide Preliminary Design Proposals And Quotations.

Conceptual And Programme Design

- Propose Innovative Product Concepts And Technical Solutions Based on Customer Requirements.

- Discuss And Iterate With Customers to Optimise And Finalise The Design Solution.

Hardware Design And Development

- Conduct Circuit Schematic Design, Chip Selection, PCB Design And Other Hardware Design Work.

- Complete Hardware Prototyping, Debugging and Verification, And Optimise According to Test Results.

Software Design and Development

- Design and Code Embedded Software, Application Software, Drivers And Other Software.

- Completion of Unit Testing, Integration Testing And System Testing of Software, and Optimisation Based on Test Results.

System Integration and Test Verification

- Integrate Hardware and Software, and Test and Verify The Function, Performance and Reliability of The Whole Machine.

- Optimise and Improve Hardware and Software According to Test Results to Ensure Product Quality.

- Assist Customers to Obtain Relevant Product Certification: Such as: CE, EMC, FCC, UL, CUL, CCC, ROHS, REACH And So On.

Trial Production and Mass Production Support

- Completion of Small Batch Trial Production, Manufacturability Analysis and Optimisation.

- Assist Customers in Mass Production Transfer and Production Support to Ensure The Quality and Delivery of Mass Production Products.

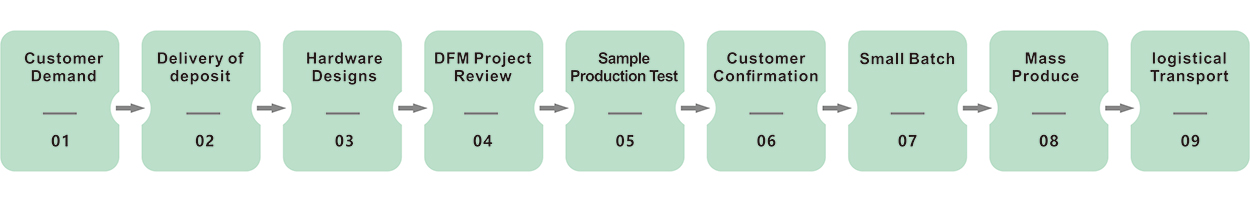

ODM Cooperation Process

Our ODM Scope of Services

|

|

|

Communication Product Design:

|

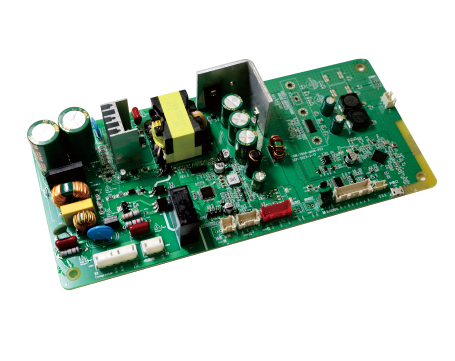

Industrial Control Product Design:

|

|

|

|

Medical Electronic Product Design:

|

Battery and Power Solutions:

|

|

|

|

Consumer Electronics Product Design:

|

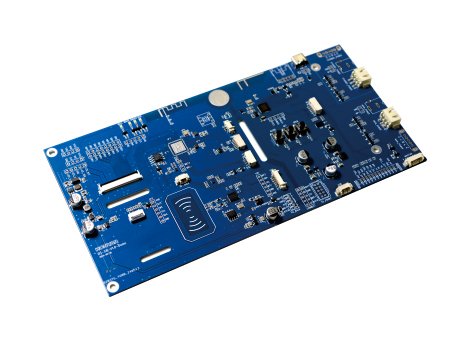

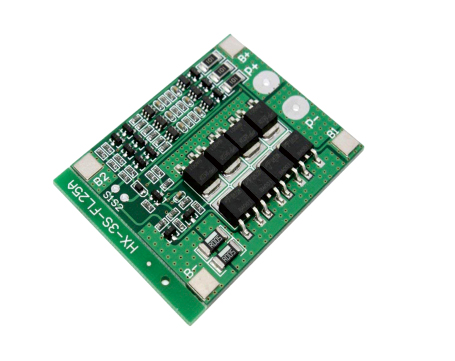

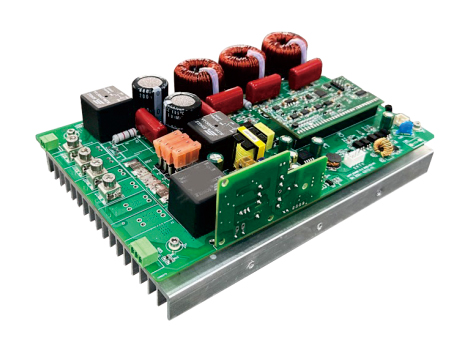

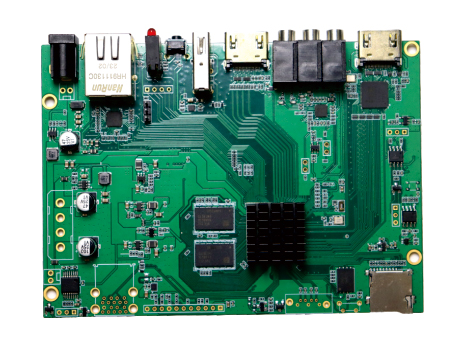

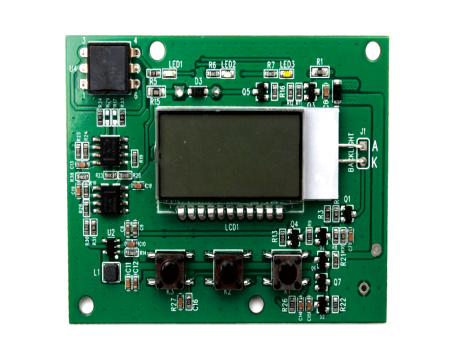

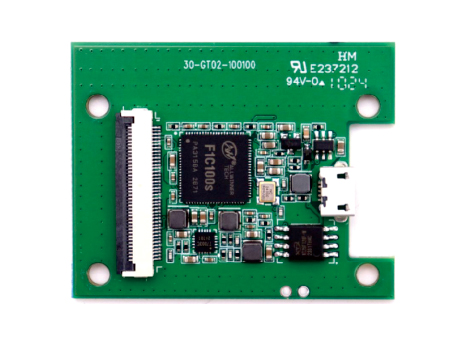

Development Case

|

|

|

| Intelligent Tea Machine | Intelligent Water | Intelligent Door Lock |

|

|

|

| BMS Protection Board | Power Control Board | Industrial Control Boards |

|

|

|

| Ultrasonic Bone Density Tester | Automated Haemostat | LCD Driver Module |

Tortai’s Design Concept

|

|

|

|

Customer-Centric Approach Always Prioritize The Needs of Our Customers, Deeply Understanding Their Business Goals, Market Positioning, And Target Audience to Tailor The Most Suitable ODM Solutions. |

Balance Innovation and Practicality Focus on Product Innovation And Practicality in Design Solutions to Ensure The Product is Not only Market-Competitive But Also Meets Users’ Real Needs. |

Quality and Reliability as the Foundation Adhere to High Quality And Reliability as The Core Standards in Product Design, Ensuring Every Product Withstands Market Scrutiny. |

|

|

|

|

Flexibility and Scalability Considerations Focus on Product Flexibility And Scalability to Adapt to Market Changes And Customer Demand Growth, Providing Support For Customers’ Long-Term Development. |

Environmental and Sustainability Concepts Integrate Environmental And Sustainability Concepts Into Product Design, Choosing Eco-Friendly Materials and Optimizing Energy Consumption to Minimize The Product’s Environmental Impact. |

Maximizing Cost-Effectiveness Ensure Product Quality And Innovation While Focusing on Cost-Effectiveness Through Refined Management And Optimized Design Processes, Helping Customers Achieve Effective Cost Control. |