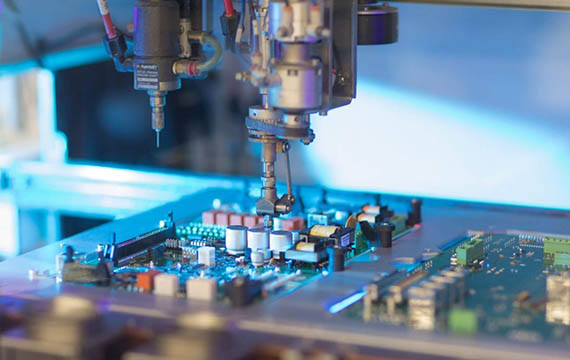

TORTAI Focuses on PCB Assembly And Manufacturing of Medical Devices to Provide You With Quality Services.

Since products in this field are closely related to human health, the highest priority must be product reliability. TORTAI fully understands that the demand in the medical field will not be as great, but the requirements for product quality will be very high. With a strong engineering team and a reliable quality control system, TORTAI is able to continue to provide reliable and efficient medical devices, and in order to meet these needs, TORTAI must ensure that its products are of high quality, safe and reliable. Quality control measures such as ISO 9001:2015, ISO14001:2015 and ISO13485 quality system standards must be implemented to ensure that all products meet the standards for safety, reliability and performance requirements.

TORTAI provides DFM reports prior to proofing, which can help customers avoid obvious errors and reduce NPI time.

We can also help customers design functional test equipment to ensure the quality of products.

TORTAI can provide test reports on welding reliability, welding process and product reliability.

Medical Electronics Assembly And Manufacturing Services

|

|

Design & Engineering• Printed Circuit Board Design • BOM Review • Rapid Prototyping |

Electronics Manufacturing• Printed Circuit Board Manufacturing • Printed Circuit Board Assembly • Integrated Manufacturing • Electromechanical assembly |

|

|

Testing and Inspection• Feed Quality Control • AOI Optical Inspection • FAI First Article Inspection • X-ray Inspection • ICT Testing • DIP Insert AOI Test • Aging Test • Functional Test • Electrical Performance Test • FCT Function Test |

Value Added Services• Component Sourcing • Logistics |

Complete Quality Certification System

ISO9001:2015, ISO13485:2016, ISO14001:2015, UL, SGS, RoHS.

Quality and service are the fundamental reasons why medium and large customers have been choosing us for a long time.

Company Overview

| Company Name | Tortai Technologies Co., Ltd. |

| Founded | 2007 |

| Company Size | 4,600 Square Metres of Production Halls |

| Quality Certification | ISO9001 Quality Management System • ISO13485 Medical Device Quality Management System •

ISO14001 Environmental Management System |

| Product Certification Scope | UL • RoHS • SGS • REACH |

| Business Scope | PCB Fabrication • Component Purchasing & Inventory Management • SMT SMD Processing • DIP Insertion Soldering • PCBA OEM • Conformal Coating • Electronic Potting • PCBA Testing • Box Build Assembly |

| value-Added Service | NPI New Product Introduction • DFX Analysis • Rapid Prototyping • Programming • SMT Stencils • Fixtures • Repair Service |

| Service Areas | Transportation • Energy • Medical • Security • Communications • AI&IoT |

| Technical Team | Electronics Engineer • BOM Engineer • Structural Engineer • Electronics Procurement Engineer |

| Production Equipment | High Speed YAMAHA SMT Machine • Nitrogen + Vacuum Reflow Oven • 10 Temperature Zones Reflow Oven • Wave Soldering • Three-proof paint automatic spraying line •Precision Potting Machine |

| Testing Equipment | Automatic Material Checker • Solder Paste Inspection (SPI) • Auto Optical Inspection (AOI)for SMT • First Article Inspection (FAI) • X-Ray Testing • In-Circuit Test (ICT) • Function Testing(FCT) • Electric Performance Testing • AOI for DIP • Aging Test |

| SMT lines | 6 assembly lines Automatic Board Loading Machine-DM900, Automatic Printing Machine-GKG Gse, 3DSPI (3D Solder Paste Inspector)-S8030, Yamaha Mounter-YSM10, Yamaha Mounter-YSM20, Nitrogen Vacuum Reflow Soldering Ovens-HX-F1030H, AOI Automatic Optical Inspection-ALD525L. |

| DIP production lines | 2 assembly lines Wave Crest Furnace -350 |

| Three-Proof Paint Spraying Line | 1 assembly line Automatic Coating Machine – iCoat-3, Infrared Curing Furnace (2 m)-iCure-2 |

| Box Build Assembly Line | 2 assembly lines |

| Automatic Precision Potting Machine | 4 table Automatic Glue Filling Machine-XH-001 |

Why Choose TORTAI

|

|

Rich Industry ExperienceWe have extensive experience in the medical industry, providing customers with DFM, DFA, DFT and other design optimisation and electronic component selection analysis. We ensure that your products are manufactured accurately and efficiently. |

Supply ChainCo-operate with international famous component channelers and original factories, guarantee the quality from the source, and effectively reduce the quality problems caused by customer supplied materials. Customised ERP material management system, component quality can be traced. Supply chain team and IQC team have more than 8 years of experience in the industry, strict quality control. |

|

|

ServiceBy business, engineering, quality of the project-type organisational structure, project-specific responsibility system as the guide, the project manager for the service specification supervisor, for pre-sales and after-sales service to provide rapid response, feedback. |

Fast ResponseTORTAI is a small to medium sized business with no cumbersome processes or multiple levels of management, and is able to respond quickly and efficiently to customer concerns, questions, production status, suggestions and more. |

Medical PCB Assembly Application Scope

1、Medical monitoring equipment: such as electrocardiographs, blood pressure monitors, etc.

2、Medical imaging equipment: such as X-ray machines, MRI, etc.

3、Medical diagnostic equipment: such as blood glucose meter, urine analyser, etc.

4、Medical surgical equipment: such as surgical robots, electric knife, etc.

5、Medical rehabilitation equipment: such as physical therapy devices, rehabilitation equipment, etc.

6、Medical auxiliary equipment: such as infusion pumps, respiratory machines, etc..

7、Medical laboratory equipment: such as centrifuges, incubators, etc.

8、Medical rescue equipment: such as first aid kit, automatic external defibrillator, etc.

9、Medical auxiliary accessories: such as medical batteries, medical sensors, etc.

10、Medical personal care equipment: such as electric toothbrush, massager and so on.

Medical PCB Assembly Manufacturing Case