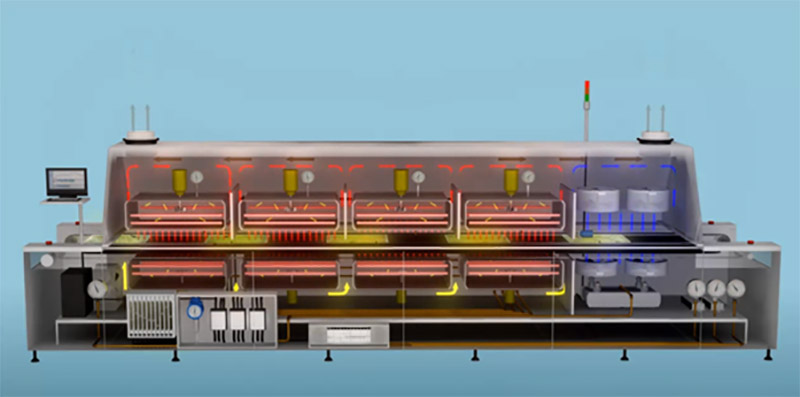

In electronics manufacturing, quality control and consistency are critical. Reflow plays a vital role in the assembly production process by heating solder paste to the correct temperature to ensure a strong and reliable connection is soldered between components and printed circuit boards (PCBs). However, as with any complex system, reflow soldering is prone to failure, which can create significant production challenges. In this post, we’ll look at some of the most common reflow soldering faults, how they can affect your production line, and what should be done to minimise their impact.

一、Fan Motor Failures

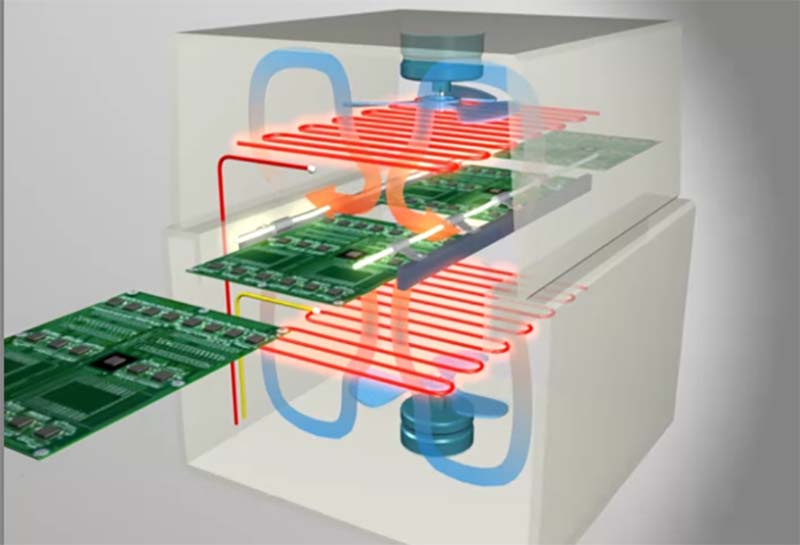

The fan motor in a reflow soldering machine is responsible for circulating hot air and ensuring even heat distribution throughout the chamber. When the motor fails, the airflow becomes inconsistent, causing the PCB to be heated unevenly. This can result in solder paste not melting properly or overheating, which can cause defects such as cold soldering or component damage.

Impact:

Poor solder quality, increased rework and higher scrap rates.

Prevention tips:

1、Regularly check and maintain the blower fans to ensure that they operate at optimal speeds

2、With hot air motor real-time monitoring system (Airflow Guard) can be in the fan motor failure before the timely detection of the problem

二、The heating zone failure

Reflow oven relies on the heating zone to generate the high temperature required for soldering. Failure of the heating zone can cause inconsistent temperatures, resulting in some parts of the PCB heated too high, while in other parts of the heat is too low. This can lead to defects such as incomplete soldering or component damage.

Impact:

Inconsistent solder quality, component damage, reduced yield.

Cold soldering, false soldering, poorly lit solder joints

Prevention Tips:

1、Routine inspection of the heating wire

2、The use of special performance test fixtures on the reflow soldering test, such as KIC SRA, to ensure that the thermal uniformity of each heating zone

3、Oven temperature real-time monitoring system (Footprint) can be in the heating zone failure caused by a sudden rise or fall in temperature alarm to alert you.

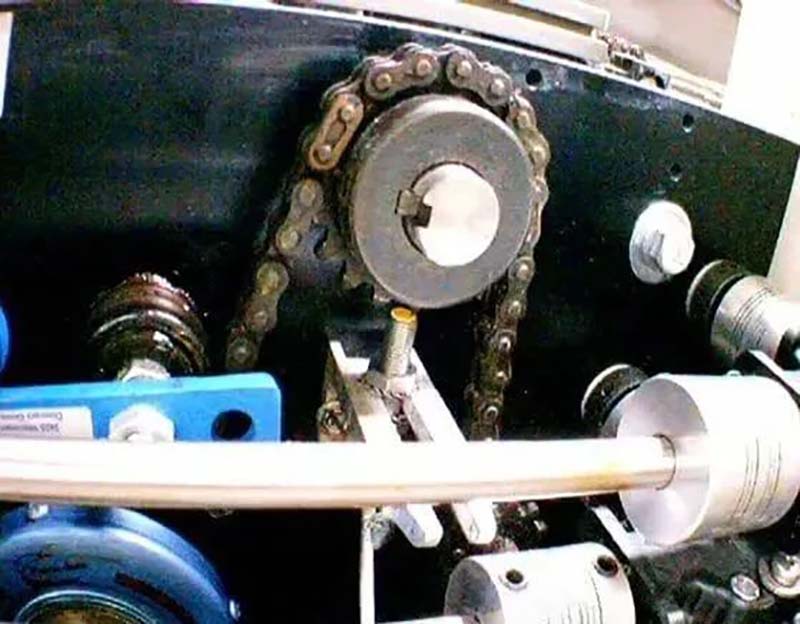

三、The chain speed deviation

The conveyor system in the reflow oven controls the speed of the PCB through different temperature zones. Over time, the conveyor belt may experience speed fluctuations, i.e. the chain speed is too fast or too slow. This can lead to improper heating of the PCB, causing problems such as poor soldering or thermal shock.

Impact:

Sharp temperature changes lead to an increase in defects such as short circuits or component breakage.

Slow speed: refuses to solder, solder joints are not shiny

Fast speeds: cold soldering, fried tin (beads), cracking

Prevention tips:

1、Regular calibration of the conveyor system

2、The use of real-time furnace temperature monitoring system (Footprint) solution for real-time monitoring of the chain speed to prevent deviations

四、The problem of fluctuating temperature

In the reflow furnace, the gradual increase in temperature is critical to avoid soldering defects. Scrambling occurs when heat from one temperature zone ‘spills over’ into neighbouring temperature zones, thus disrupting the temperature gradient required for accurate soldering. This can lead to weld defects such as voids or incomplete reflow because the furnace is unable to maintain the correct heating profile in all zones.

Impact:

Inconsistent soldering, increased defects and potential PCB damage due to improper thermal control.

Prevention Tips:

1、Avoid temperature settings between two adjacent temperature zones that exceed the maximum temperature difference of the furnace specifications

2、With reflow soldering dedicated performance test fixtures to regularly monitor each temperature zone, such as KIC SRA, to verify that each temperature zone is maintained at the set temperature, without interference from neighbouring temperature zones.

3、Furnace temperature real-time monitoring system (Footprint) can be in the temperature zone appears to run out of temperature resulting in temperature anomalies when the alarm to remind you of the

五、The hot air is not uniform

In the reflow oven, uniform hot air to ensure that each part of the PCB can be evenly heated is critical. Dirty filters, faulty fan motors, or improperly set oven temperatures can all lead to hot air problems. Inconsistent hot air results in uneven heat distribution, which can lead to defects such as solder beads, voided solder, and excess tin.

Impact:

Unreliable solder quality and increased product failures.

Void soldering, cold soldering, standing monuments

Prevention Tips:

1、Regularly clean the filter outlet and piping

2、Test the heat transfer coefficient and thermal uniformity of each temperature zone with the reflow soldering performance test fixture SRA.

3、Consider the use of hot air motor monitoring system real-time monitoring of fan motor speed and consistency of hot air

六、Cooling system

After reflow, the PCB must enter the cooling zone in a controlled manner to solidify the solder joints and prevent defects such as thermal shock. Failure of the cooling system can cause the PCB to cool too quickly or unevenly, resulting in cracks, delamination or broken solder joints. Some reflow soldering can be cooled more efficiently using water cooling or a cooler. However, there are additional risks associated with ensuring that water cooling is done correctly.

Impact:

Increased component damage and failures, costly rework, product rejection.

Prevention tips:

1、Keep the cooling system clean and functioning properly

2、Regular maintenance programme to check for any water blockages that impede water circulation.

3、With the furnace temperature real-time monitoring system (Footprint) programme in real time to detect any temperature increase in the cooling zone.

七、Over time, the mechanical components of reflow soldering (e.g. conveyor chains and gears) may wear out, resulting in inconsistent rotation. This can lead to uneven PCB transport, resulting in uneven heat exposure.

Impact:

Soldering defects, PCB misalignment, component shifting/dropping and production delays.

Prevention Tips:

1、Schedule routine mechanical inspections and replacement of worn parts to avoid disruption to the production process

2、With real-time vibration monitoring programme can be monitored in real time on the conveyor belt occurs any excessive movement and send an alarm

八、Nitrogen supply system failure (for nitrogen reflow furnace)

In a nitrogen reflow furnace, nitrogen is used to generate an inert atmosphere to prevent oxidisation during the soldering process. Failure of the nitrogen supply system can lead to oxidation of the solder joints, resulting in poor electrical connections and weakened mechanical bonds.

Impact:

Reduces weld quality and increases the chance of rework or product failure. Reduces voiding bubbles.

Prevention Tips:

1、Ensure regular maintenance of the nitrogen supply system

2、Monitor gas flow to prevent supply problems

Conclusion

Reflow oven failures are unavoidable, but with regular maintenance, line item monitoring and real-time tracking systems, you can catch them before they affect production quality. Solutions such as vibration monitoring, hot air motor monitoring and temperature and speed monitoring (Footprint) give you the tools you need to maintain consistent weld performance and minimise costly production delays.