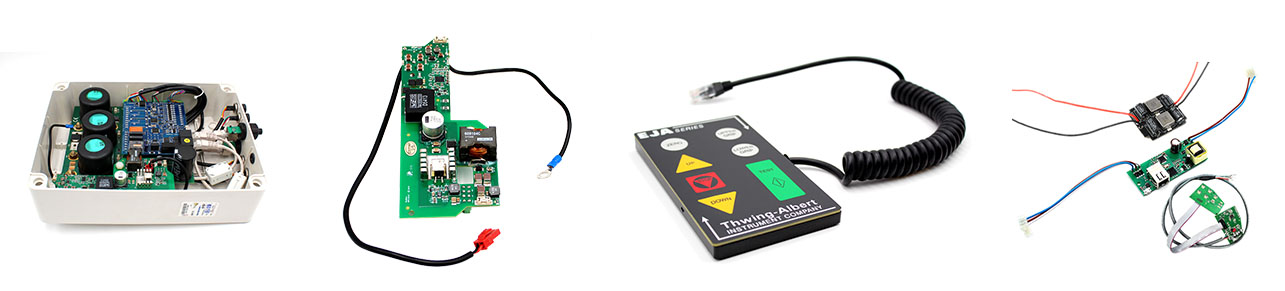

Custom Wire Harness & Cable Assembly Manufacturer

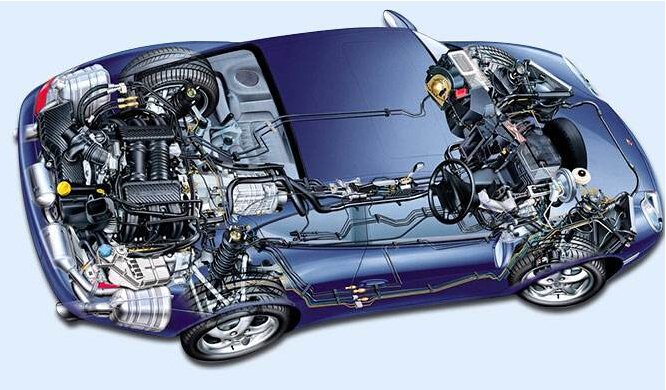

TORTAI With over 17 years of manufacturing and sourcing experience, we are well-established as a reliable supplier of high-quality cable and wire harness assemblies. Whether you need simple or complex cable assembly, TORTA offers top-tier cable assembly equipment and processes. Our cable and wire harness assembly services include AC power cable assembly, headphone assembly, generic assembly, RF cable assembly, RF antenna assembly, medical cable, automotive cable/wire harness, custom cable/wire harness, and more.

Additionally, we offer a large variety of cable assemblies to suit your business needs, ranging from simple wire harness assembly to complex pre-formed wire looms, custom over-molded solutions, and high-end RF cables.

The Power of a Strong EMS Partner

As a full-service EMS provider, TORTAI specializes in high-mix, low- to mid-volume programs. With over 17 years of manufacturing experience, we offer:

- Exceptional quality assurance

- Unique global footprint to match your manufacturing requirements

- Flexibility to expand as your program grows

- Superior supply chain and logistics management

Coaxial / RF Cable Assemblies

- Flexible & Semi Rigid

- Conformable / Complex Formed S/R

- Corrugated / Phase Matched

- Low Loss / Low Intermodal

- (0-3 GHz) – (3-8 GHz) – (8- 26.5 GHz)

- RF Test Cables (DC – 18GHz)

- Power Amplifiers

Custom Applications

- Cut / Strip / Terminate Wire, 4/0-30 gauge

- Soldering, tinning

- Automatic crimping and quality monitoring

- Connector insertion / Flat Ribbon Cable

- Label identification (128 Code or 2D)

- Continuity and hi-pot testing

- Multi-conductor cables, shielded, paired

- Simple to Complex Harness Assemblies

- Automated cut and strip machines for round cable tubing

- Automated cut and strip machines for round, Tubing

- Harness Design using 3D drawings or reverse engineering

- Test Design

- Traceability for every process step

From concept to finished and tested cable assemblies or equipment sub systems, TORTAI provides comprehensive manufacturing of high quality cable harness assemblies and cable systems for connectivity, industrial, medical, automotive and display technology marketplaces.

Complementary Specialist Services Include:

- Heat shrink systems

- Conduit assemblies

- Open looming – internal cable harnessing

- Over-braiding of cable

Variety of Cable and Harness Assembly Capabilities:

- Discrete Wires 30-10 AWG

- End terminated

- Single or Multi-wire and Bundled

- Multi discrete of (DC) Power, Signal & Coaxial

- Sub-assembly / Kitting

- Hardware & Ancillary equipment

- Wire Wrap using X-Y Machine

- FFC (Flat Flex Cable)

TORTAI Provide a Comprehensive Product Offering of Cable Assembly Solutions:

- Discrete and complex wire harnesses

- Encapsulation molded cable assemblies

- System wiring for internal and external interconnects

- Custom/application-specific cable assemblies

- Electro-mechanical subassemblies

Our state-of-the-art facilities offer the latest in cable technologies to create the ideal environment to meet our customers’ requirements.